- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

SUOYI Ready to Press Alumina Granulated Powder for Ceramic

|

Item |

Value |

|

Classification |

ALUMINA |

|

CAS No. |

1344-28-1 |

|

Other Names |

Alumina |

|

MF |

Al2O3 |

|

EINECS No. |

215-691-6 |

|

Place of Origin |

China Hebei |

|

Grade Standard |

Industrial Grade, Reagent Grade |

|

Purity |

99.5%-99.7% |

|

Appearance |

White Powder |

|

Application |

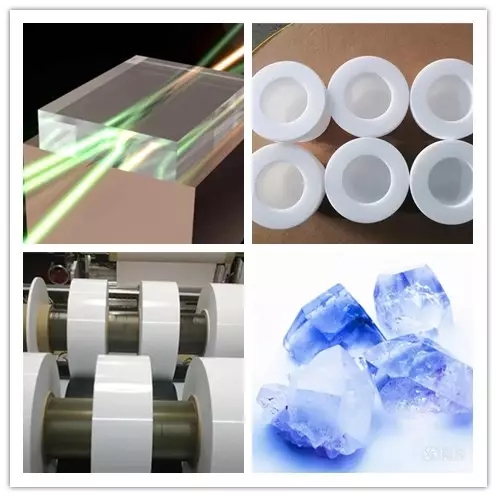

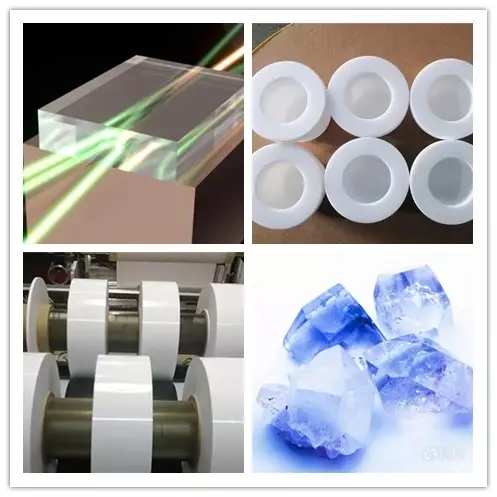

Electronic ceramics, structural ceramic components |

|

Brand Name |

Suoyi |

|

Model Number |

DZ99A |

|

Molecular weight |

101.96 |

CP SERIES ALUMINA CERAMIC GRANULATED POWDER

Dry pressing and isostatic voltage production of electronic ceramics and structural ceramics

01

Medium solid particles, reasonable particle size distribution, moderate strength

Good fluidity and easy demoulding

High strength of green body, high density of porcelain

Alumina is a stable oxide of aluminum with the chemical formula Al2O3. Also known as bauxite in mining, ceramics and materials science.

Properties: White solid insoluble in water, odorless, tasteless, extremely hard, easy to absorb moisture but not deliquescence (burned does not absorb moisture). Alumina is a typical amphoteric oxide (corundum is α-shaped and belongs to the hexagonal closest packing, is an inert compound, slightly soluble in acid and alkali corrosion resistance ), soluble in inorganic acid and alkaline solution, almost insoluble in water And non-polar organic solvent; relative density (d204) 4.0; melting point 2050 ºC.

Storage: sealed and dry.

Uses: used as analytical reagents, dehydration of organic solvents, adsorbents, organic reaction catalysts, abrasives, polishing agents, raw materials for aluminum smelting, and refractory materials.

Alumina is suitable for a variety of wet and dry processing processes, and is one of the most economical abrasives for grinding the rough surface of any workpiece to a finer finish. This kind of artificial synthetic abrasive with sharp water chestnuts has a hardness second only to diamond, and is especially suitable for use when there are strict requirements for iron pollution. For the roughest cuts, it can also be made into a pebble shape to process precision-sized workpieces to achieve very low roughness. It is one of the fastest cutting abrasives due to its high density, sharp, water chestnut structure.

Alumina is produced by electro-melting high-quality bauxite ore to produce brown corundum, while high-quality aluminates are used to produce powder and white corundum. Their natural crystal structure gives them high hardness and fast cutting performance. At the same time they are often used as raw materials for bonded and coated abrasives.

Alumina can be recycled multiple times, depending on the material grade and specific process, and can be used with most standard abrasive blasting equipment.

Applicable industries: aerospace industry, automotive industry, consumer goods processing, casting/die casting, OEM distributors, semiconductor industry and other fields.

Applicable process scope: pretreatment before surface plating, painting, glazing and PTFE coating; deburring and descaling of aluminum and alloy products; mold cleaning; pretreatment before metal blasting; dry grinding and wet grinding; Precision optical refraction; grinding of minerals, metals, glass and crystals; glass engraving and paint additives.

Used as analytical reagents, dehydration of organic solvents, adsorbents, organic reaction catalysts, abrasives, polishing agents, raw materials for aluminum smelting, and refractory materials.

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director