- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

SUOYI Industrial grade aluminum titanium oxide powder Mixture of alumina and titania powder AT40 for plasma spraying

|

item |

value |

|

Classification |

Mixture of alumina and titania |

|

CAS No. |

12004-39-6 |

|

MF |

Al2O5Ti |

|

EINECS No. |

215-691-6 |

|

Place of Origin |

China |

|

Grade Standard |

Electron Grade, Industrial Grade, Reagent Grade |

|

Purity |

TiO2 40% |

|

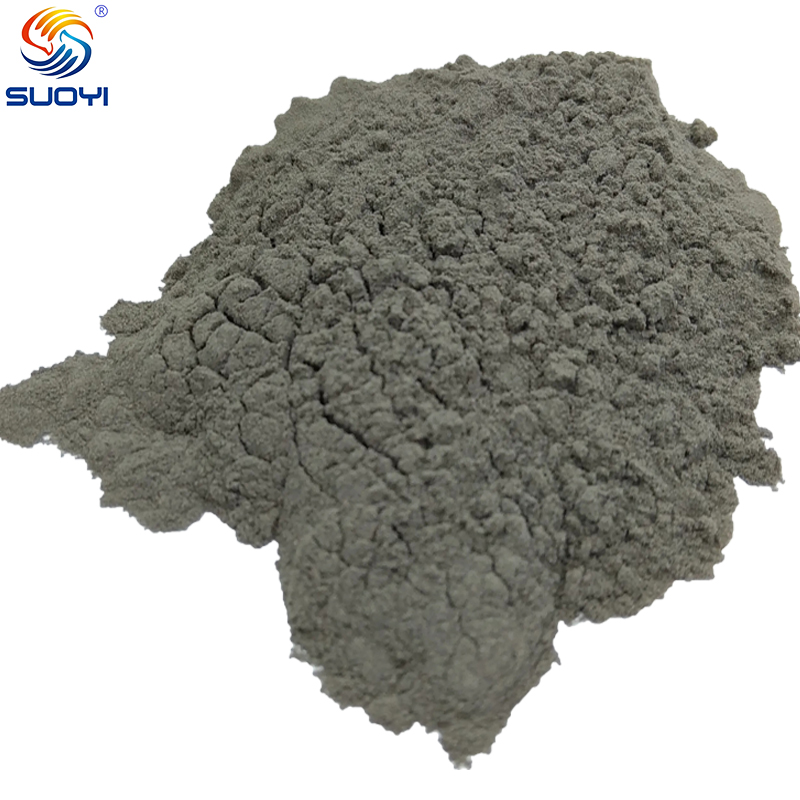

Appearance |

whitepowder |

|

Application |

Sparying Coating |

|

Brand Name |

SUOYI |

|

Model Number |

SY-AT40 |

|

Product name |

titanium alumina |

|

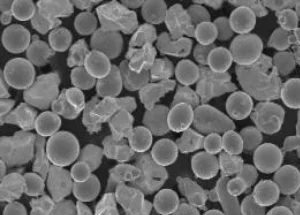

partical size |

45-90 |

|

Properties |

white amorphous powder |

|

Density (g/mL, 25/4℃) |

3.73 |

|

Melting point (ºC) |

1860 |

|

Solubility |

Insoluble in water |

|

MOQ |

25kg |

|

Packing |

25kg/drum |

|

Application |

Manufacture of special glass |

Dialuminium titanium pentaoxide, the molecular formula is Al2O5Ti, and the molecular weight is 181.8271. The main purpose 1. Used in the manufacture of special glass, ceramic binders and coatings, etc. Aluminum titanate material has extremely excellent thermal shock resistance and thermal stability. This material is used in harsh environments such as high temperature, strong corrosion and thermal shock. The research and development of aluminum titanate ceramic riser tubes, thermocouple protection tubes, crucibles, aluminum titanate and aluminum alloy composite exhaust pipes, exhaust ducts, Series products such as volutes have been widely used in the non-ferrous metallurgical industry and other fields such as thermal shock resistance and heat insulation. In addition, it can also be used for the preparation of thermocouple temperature measurement protection tubes, furnace lining and furnace body insulating refractory materials for non-ferrous metal smelting, and quick-burning saggers.

Applications

This ceramis powder with high hardness and excellent abrasion resistance, suitable to work under 500℃ , suitable for coating of components piston rings,rollers ,high pressure gate valves and other high pressure components. But it is not suitable to work above 500℃ and in erosive environment.

Recommended Spray Process :HVOF , HVAF , APS, etc.

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director