- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

SUOYI High purity si silicon metal powder 325 mesh silicon metal powder polysilicon metallic silicon

|

item |

value |

|

Place of Origin |

China |

|

Hebei |

|

|

Brand Name |

SUOYI |

|

Model Number |

SYSI |

|

Application |

Semiconductor material or alloy |

|

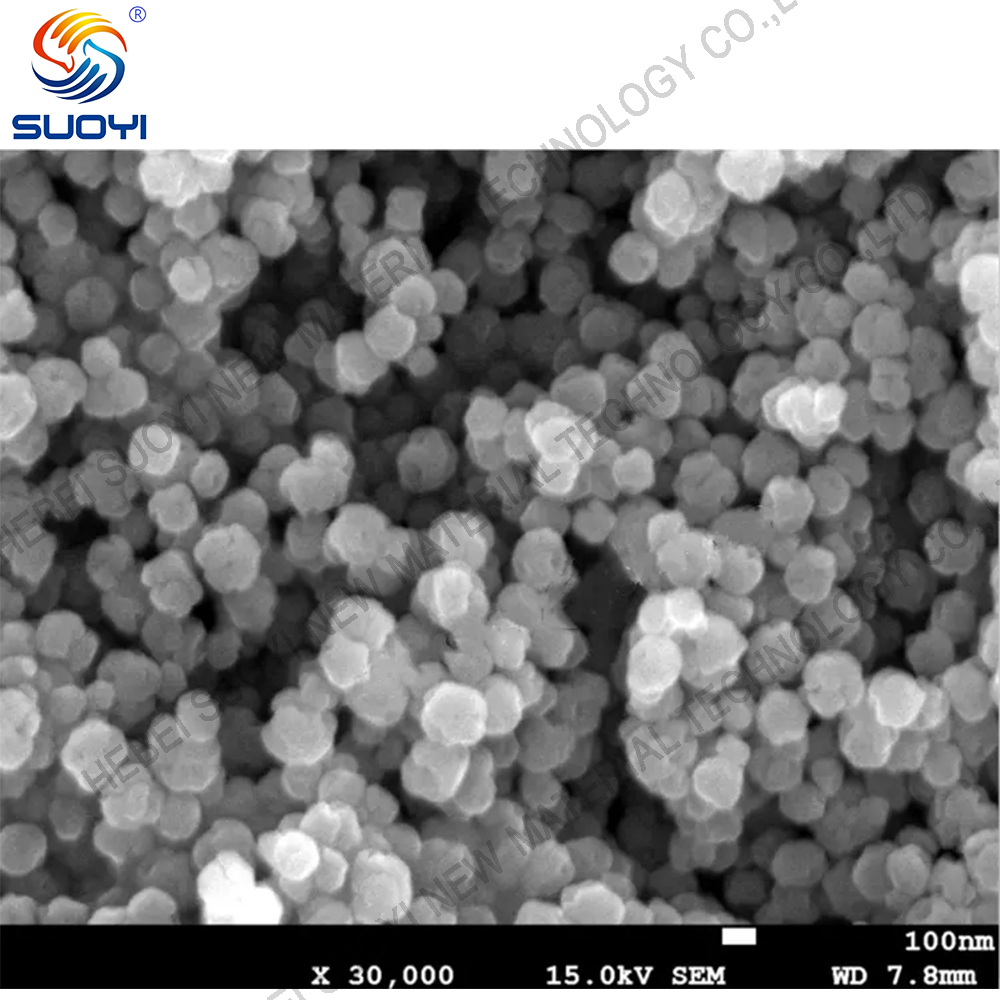

Shape |

Spherical |

|

Material |

Silicon |

|

Chemical Composition |

Si |

|

Product name |

Silicon Metal Powder |

|

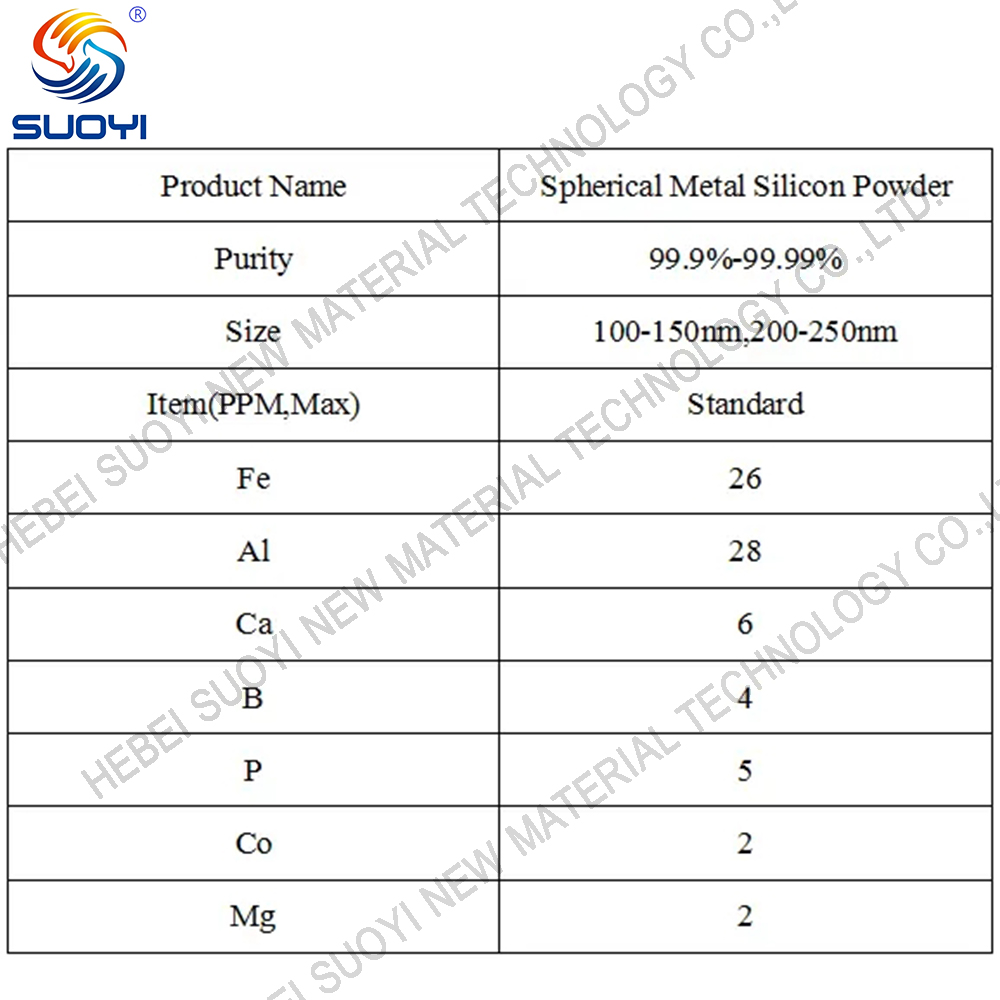

Purity |

99.9%min |

|

Color |

Gray metallic luster |

|

CAS No |

7440-21-3 |

|

EINECS No |

231-130-8 |

|

Boiling point |

2355℃ |

|

Melting Point |

1410℃ |

|

Density |

2.33 |

|

MOQ |

1 Kg |

|

Payment Term |

TT,LC |

|

Silicon powder |

Specification |

Min. Si content |

Chemical composition% |

||

|

Max impurity content |

|||||

|

Fe |

Al |

Ca |

|||

|

Silicon powder for chemical egineering |

Si- (20-120 mesh) |

99.0 |

0.4 |

0.4 |

0.1 |

|

Si- (30-140 mesh) |

99.0 |

0.4 |

0.4 |

0.1 |

|

|

Si- (40-160 mesh) |

99.0 |

0.4 |

0.4 |

0.1 |

|

|

Si- (40-280 mesh) |

99.0 |

0.4 |

0.4 |

0.1 |

|

|

Si- (40-325 mesh) |

99.0 |

0.4 |

0.4 |

0.1 |

|

|

Silicon powder for refractory material |

150 mesh |

98.5 |

0.5 |

0.5 |

0.3 |

|

200 mesh |

98.5 |

0.5 |

0.5 |

0.3 |

|

|

325 mesh |

98.5 |

0.5 |

0.5 |

0.3 |

|

|

400 mesh |

98.5 |

0.5 |

0.5 |

0.3 |

|

|

500 mesh |

98.5 |

0.5 |

0.5 |

0.3 |

|

|

Low grade silicon powder |

200 mesh 325 mesh |

97 |

Impurity contents≤3.0% |

||

| Product: 553#, 521#, 421#, 3303# Particle size: 20-160mesh, 30-270mesh,45-710um,200mesh and 325mesh,etc. | |||||

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director