- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

SUOYI High Pure CAS 12070-08-5 Dark Gray Metal Titanium Carbide Ti Metal Tic Powder Used as Plasma Spray Coating Powder

| Application | conductivity |

| Shape | Powder |

| Material | titanium carbide |

| Chemical Composition | TiC |

| CAS No | 12070-08-5 |

| ENINEC No | 235-120-4 |

| MF | TiC |

| Grade Standard | General Reagent |

| Purity | 99.5% |

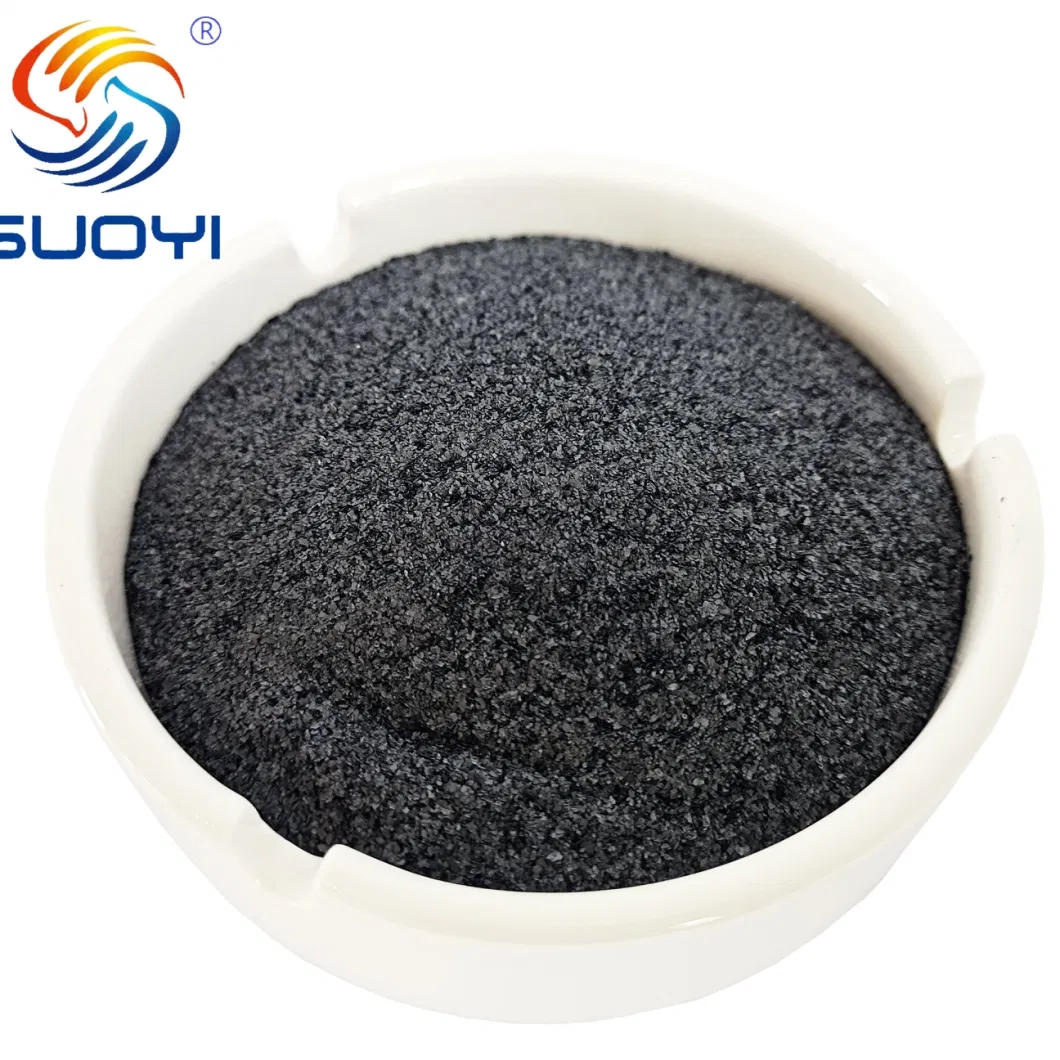

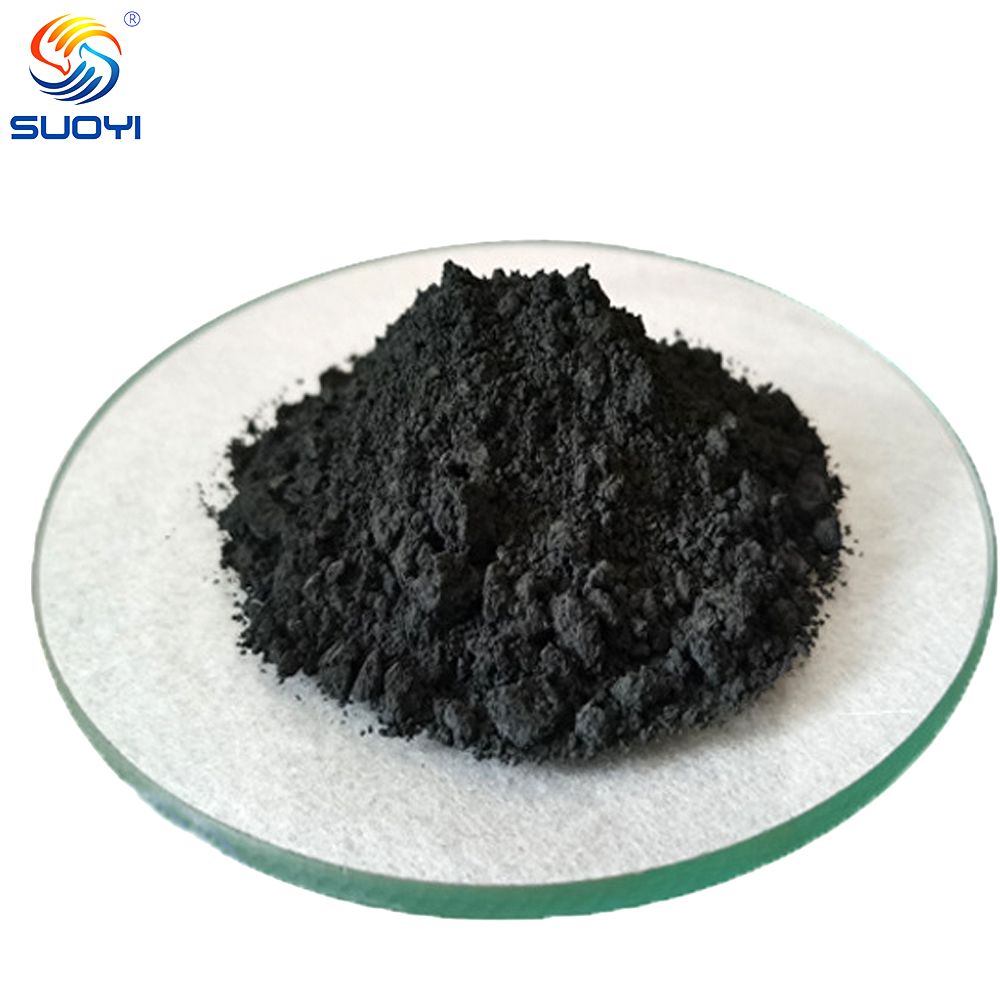

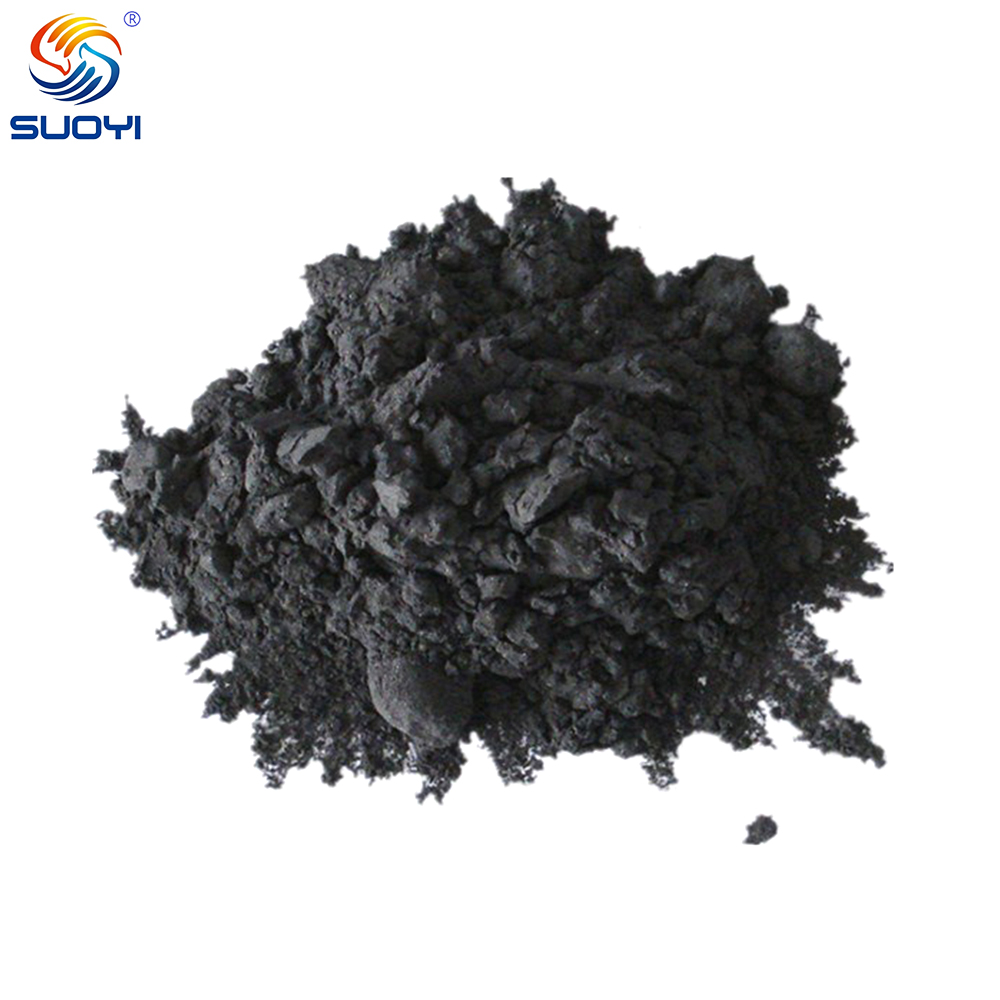

| Appearance | Black Powder |

| Sample lead time | 1-5days |

| Delivery way | DHL, UPS, Fedex, TNT |

| Packaging Details | titanium carbide TiC nanopowder sale price is available of 100g/bag, 500g/bag, 1kg/bag, according to customer's requirements. |

| Port | Shanghai,Shenzhen,Tianjin |

|

Product name |

Titanium carbide Powder |

|

MF |

TiC |

|

Grade Standard |

Industrial Grade |

|

Purity |

99.9%min |

|

Color |

Black Color |

|

Usage |

Cermet, wear-resistant film |

|

MOQ |

1 KG |

|

Keywords |

TiC powder |

|

Sample |

Availiable |

|

Shape |

Powdery |

|

Package |

Barrel or Customized |

|

Delivery way |

Optional |

|

Delivery Time |

3-15 Days |

01

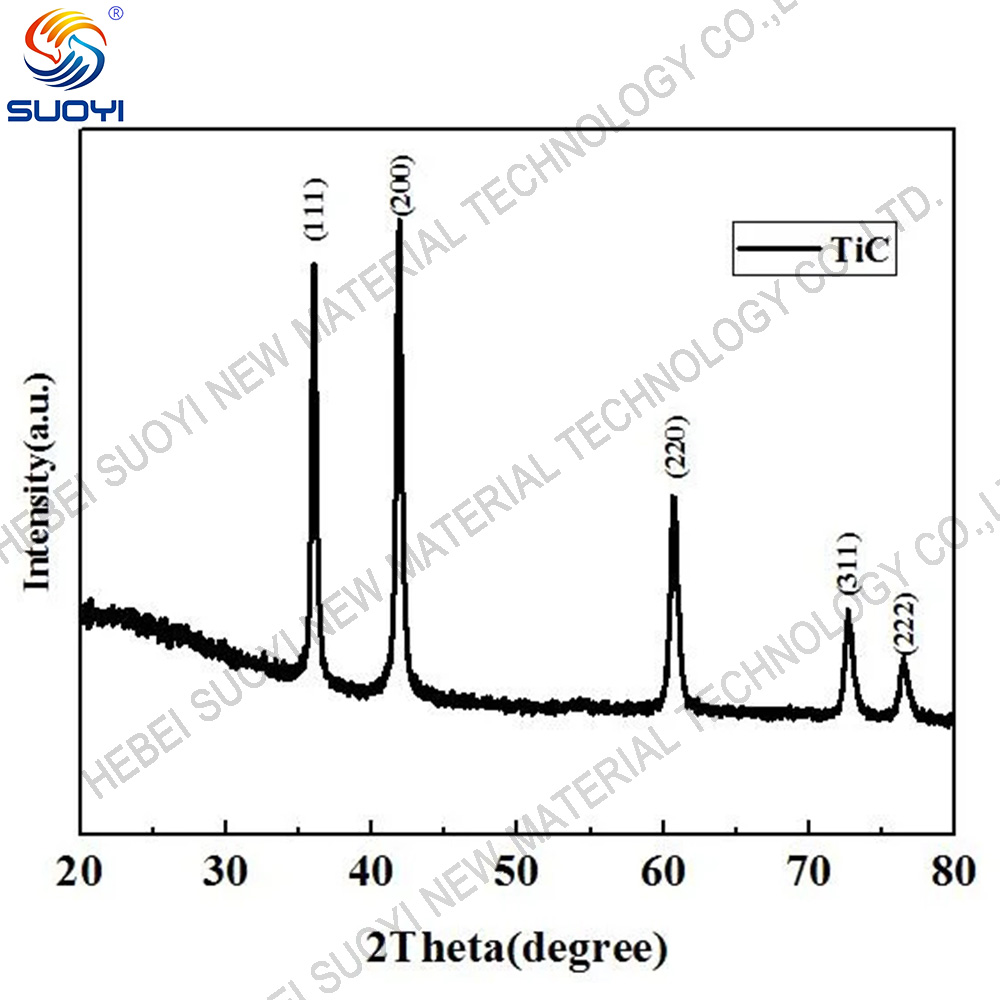

Titanium carbide is a gray white metallic powder with a NaCl type cubic crystal structure. Its density is 4.93 g/cm3, the melting point is 3160 ℃, and the boiling point is 4300 ℃.

Due to its high melting point, high hardness, and good chemical stability, it is mainly used to manufacture metal ceramics, heat-resistant alloys, hard alloys, high-temperature resistant thermal spraying materials, welding materials, hard film materials, aviation materials and so on.

|

Part No. |

Particle |

Purity(%) |

SSA(m2/g) |

Bulk density(g/cm3) |

Density(g/cm3) |

Crystal |

Color |

|

SYCP2206-50N |

50nm |

99.9 |

65 |

0.56 |

4.8 |

Cubic |

black |

|

SYCP2206-100N |

100nm |

99.9 |

25 |

1.23 |

4.8 |

Cubic |

black |

|

SYCP2206-1U |

1-3um |

99.9 |

10 |

3.24 |

4.8 |

Cubic |

black |

1. Titanium carbide Nanoparticles are the hardest of the transition metal carbides, but they are too fragile to be used pure. They are added in percentages of 5-30% (by weight) to cemented tungsten-based carbides to increase the hardness and resistance to high-temperature cutting tools.

2. Sometimes TiC is used to cover the cutting surfaces of these tools. Tungsten-free cutting tool bits can be obtained by combining TiC Nanoparticles, molybdenum carbide, and nickel.

3. Titanium Caribe Nanoparticles are used as alloy additives.

4. Titanium Caribe Nanoparticles are used as surface materials.

5. This compound has excelled in the production of grinding, grinding wheel, etc.

6. Titanium Caribe is used as welding and current drilled wire.

7. Titanium Caribe Nanoparticles are used in the preparation of cermet.

8. Titanium Caribe Nanoparticles are used for abrasion-resistant surface coating on metal parts, such as tool bits.

9. Titanium Caribe Nanoparticles are used for heat shield coating for atmospheric return of spacecraft.

10. TiC is also used in general toolmaking and in the chemical industry as an essential component of the sintered material ferrotitanium.

11. Titanium Caribe Nanoparticles are used in the production of wear-resistant materials, sharp tools, etc.

12. Titanium Caribe Nanoparticles coating can improve the alloy, abrasive steel bearings, pipes, and cutting tools.

13. They are used in the preparation of titanium-foamed ceramic material. The foamed ceramic incorporates filters for any type of fluid containment to work effectively, except that the filtration mechanism agitates the adsorption.

14. The application of the Titanium Carbide Nanoparticles layers for metal forming takes place by the CVD process at about 1000 °C. This ensures maximum adhesion. The higher layer thickness of up to 9 μm, which is possible due to the CVD process, is a welcome wear reserve for many applications.

15. Titanium Carbide Nanoparticles have become the basis of modern high-hardness materials, heat-resistant electrodes industrial arc lamps, wear-resistant drilling equipment, and special tools. In powder form, it is used as an additive to graphite and as a substitute for graphite.

16. In electrolysis, TiC serves as an electrode together with cathode. Such electrodes are indispensable in the electro-autogenous cutting of steel underwater - they allow 6-10 times lower consumption of the electrode, compared to conventional electrodes. Titanium Carbide electrodes have the following composition: Ti 79.2-80%; C of 0.1 to 0.2%; C tot. 19.4 - 20.2%; Fe 0.1 - 0.6%.

17. TiC nanoparticles are used for the coating of graphite electrodes of electric arc furnaces.

18. TiC nanoparticles are also used in the production of heat-resistant screens of combustion plants, seat covers thermocouples, housing crucibles, boats, glass, semiconductors, metals, and non-metals.

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director