- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

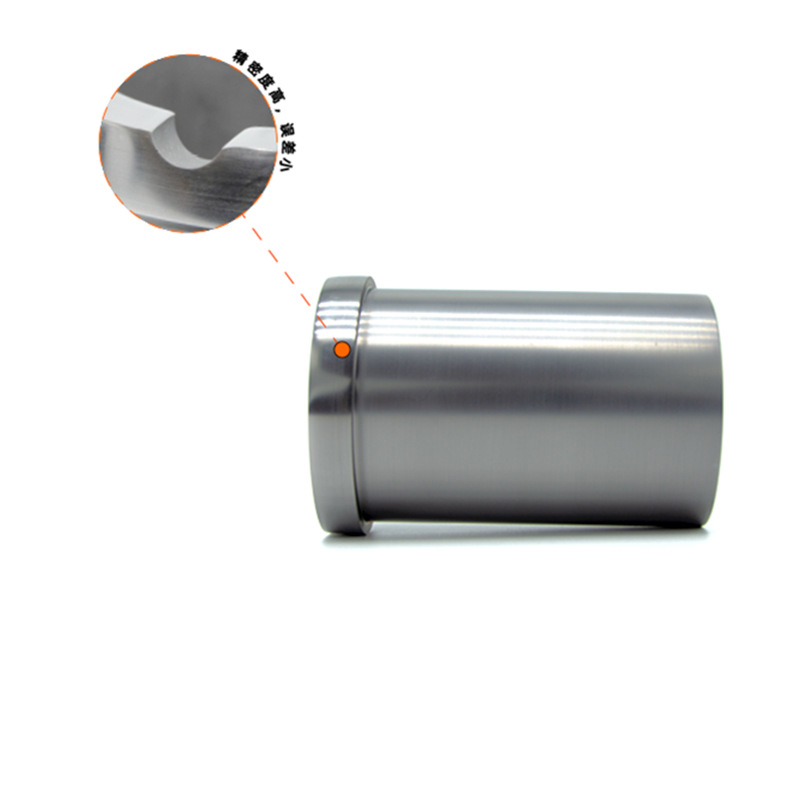

SUOYI Graphite crucible SiC Crucible Anti Oxidation Copper Silicon Carbide Graphite Crucible

Graphite crucible has good thermal conductivity and high temperature resistance. During high temperature use, the thermal expansion coefficient is small, and it has certain strain resistance to rapid heating and cooling. It has strong corrosion resistance to acid and alkaline solutions and excellent chemical stability. In metallurgy, casting, machinery, chemical industry and other industrial sectors, it is widely used in the smelting of alloy tool steel and the smelting of non-ferrous metals and their alloys, and has good technical and economic effects. Graphite crucible has good thermal conductivity and high temperature resistance. During high temperature use, the thermal expansion coefficient is small, and it has certain strain resistance to rapid heating and cooling. It has strong corrosion resistance to acid and alkaline solutions and excellent chemical stability. In metallurgy, casting, machinery, chemical industry and other industrial sectors, it is widely used in the smelting of alloy tool steel and the smelting of non-ferrous metals and their alloys, and has good technical and economic effects.

High-quality Chinese graphite crucibles have the following characteristics:

1. The high density of graphite crucible enables the crucible to have the best thermal conductivity, and its thermal conductivity effect is significantly better than other imported crucibles;

2. The graphite crucible has a special glaze layer and dense molding material on the outside, which greatly improves the corrosion resistance of the product and extends its service life;

3. The graphite components in the graphite crucible are all natural graphite, which has very good thermal conductivity. Do not place the graphite crucible on a cold metal table immediately after heating to avoid cracking due to rapid cooling.

| Item | Ⅰ | Ⅱ | Test Method | ||

| Forming method | Plasticity (S) | Isostatic pressure (D) | Plasticity (S) | Isostatic pressure(D) | |

| Carbon content /% | ≥ 38 | ≥ 45 | ≥ 38 | ≥ 45 | GB/T 1655-2008 |

| Bulk density /(g/cm3) | ≥ 1.70 | ≥ 1.85 | ≥ 1.70 | ≥ 1.85 | GB/T 2997-2000 |

| Porosity /% | ≤ 29 | ≤ 21 | ≤ 29 | ≤ 21 | GB/T 2997-2000 |

| Normal temperature compressive strength /MPa | ≥ 20 | ≥ 25 | ≥ 20 | ≥ 25 | GB/T 5072.2-2004 |

| Fire resistance / ℃ | ≥ 1500 | ≥ 1500 | ≥ 1400 | ≥ 1400 | GB/T 7322-2007; Antioxidant glaze coating |

| Model | Upper port outside diameter ±2% | Thickness | Lower bottom outside diameter ±2% | Height ±2% |

| 1# | 67 | 8± 1.0 | 35 | 65 |

| 1.5# | 78 | 10± 1.0 | 60 | 80 |

| 2# | 88 | 10± 1.0 | 62 | 100 |

| 3# | 100 | 12± 1.0 | 75 | 115 |

| 4# | 115 | 12± 1.0 | 85 | 115 |

| 5# | 122 | 13± 1.0 | 85 | 138 |

| 6# | 125 | 14 ± 1.0 | 85 | 155 |

| 41# | 215 | 19~ 21.5 | 150 | 290 |

| 45# | 250 | 19~ 21.5 | 180 | 295 |

| 70# | 285 | 19~ 21.5 | 215 | 245 |

| 80# | 310 | 20~ 22.5 | 210 | 370 |

| 90# | 320 | 21~ 23.5 | 230 | 385 |

| 100# | 314 | 21~ 23.5 | 220 | 408 |

| 200# | 400 | 23~ 25.5 | 290 | 475 |

| 260# | 416 | 24~ 26.5 | 250 | 585 |

| 300# | 452 | 26~ 29 | 310 | 580 |

| 360# | 462 | 28~ 31 | 342 | 674 |

| 390# | 530 | 28~ 31 | 410 | 560 |

| 400# | 515 | 29~ 32 | 340 | 600 |

| 420# | 515 | 29~ 32 | 330 | 673 |

| 440# | 620 | 29~ 32 | 340 | 500 |

| 450# | 516 | 32~ 35 | 340 | 710 |

| 530# | 580 | 31~ 34 | 330 | 635 |

| 560# | 590 | 33~ 36 | 330 | 690 |

| 570# | 620 | 33~ 36 | 335 | 570 |

| 580# | 545 | 33~ 36 | 317 | 750 |

| 610# | 607 | 34~ 38 | 350 | 630 |

| 680# | 585 | 34~ 38 | 330 | 760 |

| 690# | 600 | 34~ 38 | 330 | 805 |

| 700# | 615 | 34~ 38 | 350 | 758 |

| 840# | 700 | 35~ 39 | 470 | 675 |

| 950# | 720 | 37~ 41 | 300 | 740 |

| 970# | 720 | 34~ 38 | 470 | 730 |

| 1100# | 715 | 35~ 39 | 478 | 846 |

| 1150# | 855 | 42~ 46 | 340 | 677 |

| 1200# | 780 | 36~ 40 | 450 | 752 |

| 1250# | 725 | 36~ 40 | 470 | 905 |

| 1500# | 784 | 37~ 41 | 450 | 890 |

| 1700# | 778 | 40~ 44 | 442 | 1050 |

| 2500# | 880 | 44~ 48 | 350 | 1150 |

Note: Standard type graphite crucible specifications refer to the national standard GB/T 26279-2010.

hure purity Graphite crucible/cast iron crucible

Graphite crucible is a crucible made of graphite, silicon carbide, clay, silica, wax stone, pitch and tar, etc. fired as raw materials. The material used for graphite crucible is made of high purity, high strength and high density graphite refractory material, which can be made into graphite crucible, graphite casting crucible and graphite oil tank through CNC processing.

1. Good thermal stability of graphite crucible: special formula for the use conditions of graphite crucible of rapid heat and cold.

2. Good corrosion resistance and impact resistance of graphite crucible to ensure the reliability of product quality.

3. Good resistance to strong acid and alkali of graphite crucible.

4. Good heat conduction performance of graphite crucible: it can greatly shorten the melting time and save energy.

5. The ash content of graphite crucible is less than 300pp to ensure that the precious metals are not polluted in smelting.

Graphite crucible is mainly used to melt non-ferrous metals such as purple copper, brass, gold, silver, zinc and lead and their alloys.

Note.

1. Storage: place in a dry place, not wet.

2. Handling: Handle with care and do not collide.

3. Placement: Use the correct crucible holder and make sure that the crucible base is firmly in contact.

4. Charging: Fill the crucible with ingots or scrap metal carefully, do not squeeze hard and do not insert and squeeze too closely.

5. Adding melt: Use as little melt as possible.

6. Cleaning: Keep the crucible clean, pour out the residual metal quickly at the end of the operation and remove the residue carefully.

7. Drying and preheating: If the crucible is damp, it needs to be dried slowly at a temperature below 100 °C.

8. Water removal: Remove all water around the furnace to avoid leakage causing metal and water contact to fry.

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director