- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

SUOYI Factory Price High purity Zn Powder Zinc Metal Powder for chemical production Industrial Grade Zinc Powder CAS No. 7440-66-6

|

item |

value |

|

Shape |

Spherical Metal powder |

|

Material |

Spherical zinc powder |

|

Chemical Composition |

Spherical zinc powder |

|

Product name |

Spherical zinc powder, Zn |

|

Place of Origin |

HeBei, China |

|

Brand Name |

SUOYI |

|

Application |

Coating |

|

CAS NO. |

7440-66-6 |

|

MOQ |

1kg |

|

Package |

Vacuum Package |

|

Appearance |

Spherical powder |

|

Product |

Zn |

|

|

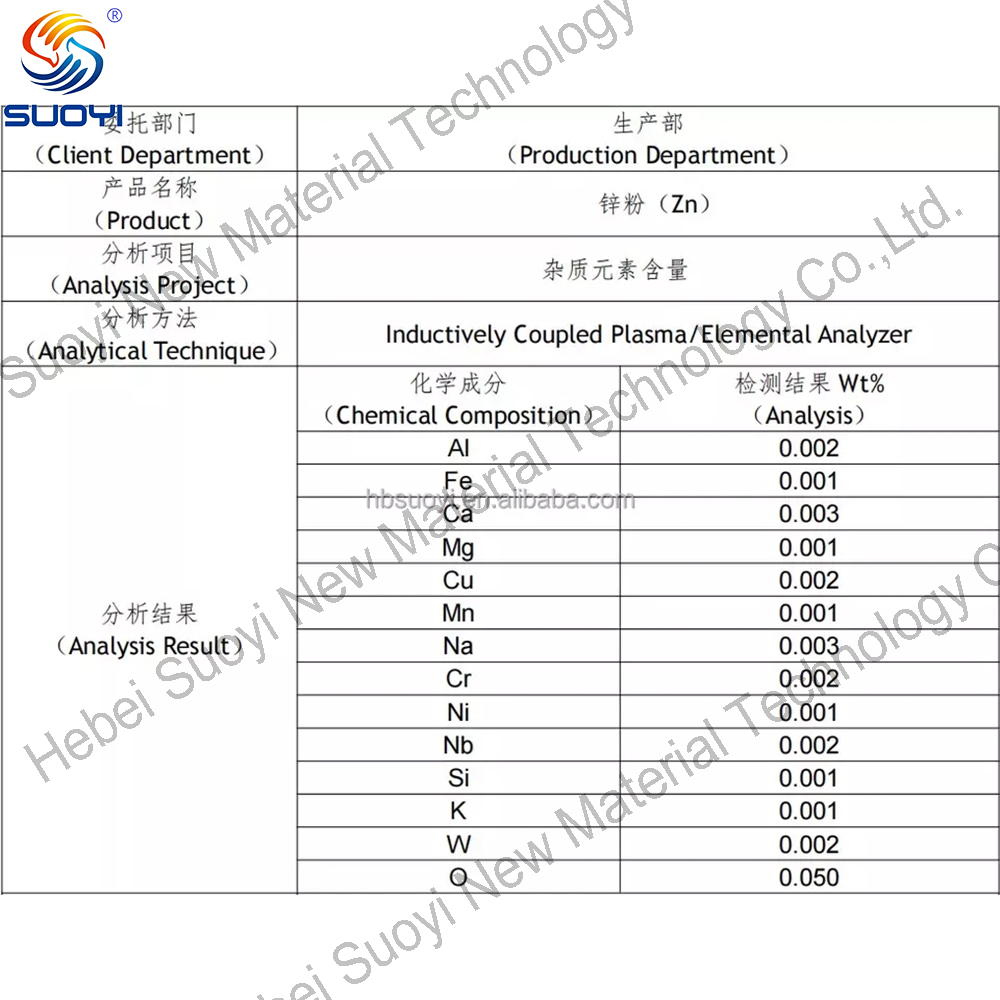

Analysis Project |

Impurity element content |

|

|

Analysis Technique |

Lndcutivrly CoupletPlasma/Elemental Analyzer |

|

|

Analysis Result |

Chemical Composition |

Chemicalcontent(%) |

|

Zn |

99.9 |

|

|

Pb |

≤0.04 |

|

|

Fe |

≤0.03 |

|

|

Cd |

≤0.03 |

|

|

Size |

20-30um |

|

Used as paint pigments and rubber fillers. The abbreviation for a dental filling material used in medicine to make ointment, zinc paste, adhesive plaster, etc., namely clove oil zinc oxide cement powder.

Clove oil zinc oxide cement powder: also known as temporary cement powder, butoxy ointment. Used as a non-stress-bearing material for the bottom layer of a deep hole, or a single-layer material that is not load-bearing. It is used as a temporary sealing material for cavities for 1 to 2 weeks. It is also used as a root canal filling material. Adding excipients as a periodontal plug treatment Agent.

Doctors often use zinc oxide as the abbreviation for clove oil zinc oxide cement.

The calamine lotion used to treat acute pruritic skin diseases usually also contains zinc oxide, which uses the astringent and protective effects of zinc oxide, as well as a small part of the antiseptic effect.

Zinc oxide is an indispensable additive in the rubber and tire industries. It is also used as a vulcanization activator, reinforcing agent and coloring agent for natural rubber, synthetic rubber and latex. If ordinary zinc oxide is made into nano-zinc oxide and used in rubber, it can give full play to the vulcanization acceleration effect and improve the performance of rubber, and its dosage is only 30%-50% of ordinary zinc oxide.

In the chemical industry, zinc oxide is widely used as a catalyst and desulfurizer, such as a catalyst when synthesizing methanol, and a desulfurizer when synthesizing ammonia; the high surface activity of nano-zinc oxide can improve the selective performance and catalytic efficiency of the catalyst, and has a wide range of potential Application market.

In the coating industry, in addition to its tinting power and hiding power, zinc oxide is also an antiseptic and luminescent agent in coatings; in addition, the excellent ultraviolet shielding ability of nano-zinc oxide makes it more prominent in the anti-aging properties of coatings. characteristic.

In the medical and health and food industries, zinc oxide has the functions of removing toxins, hemostasis, and astringent muscle growth. It is also used as a raw material for adhesive plasters, and it is helpful to promote children’s intellectual development; the demand for nano-zinc oxide in the food hygiene industry is gradually increasing Expanded, but the product requirements are also stricter, especially the content of harmful heavy metal elements.

In the glass industry, zinc oxide is used in special glass products; in the ceramic industry, zinc oxide is used as a flux; in the printing and dyeing industry, zinc oxide is used as an anti-dyeing agent; nano-zinc oxide is Reduce the sintering temperature of glass and ceramics. In addition, the ceramic glaze prepared by nano-zinc oxide is more smooth and has the functions of antibacterial, anti-enzyme, and deodorizing.

In the electronics industry, zinc oxide is not only the main raw material for varistors, but also the main additive for magnetic and optical materials. The use of nano-zinc oxide to prepare varistor not only has a lower sintering temperature, but also improves the performance of the varistor, such as flow capacity, nonlinear coefficient, etc. The application of nano-zinc oxide in optical devices will make a big breakthrough with the in-depth study of the optical properties of nano-zinc oxide.

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director