- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

SUOYI 99.9% 0.3-0.5um 1um 2-3um 200mesh Black Boron Carbide CAS 12069-32-8-copy

|

Name |

Zirconium carbide |

|

Formula |

ZrC |

|

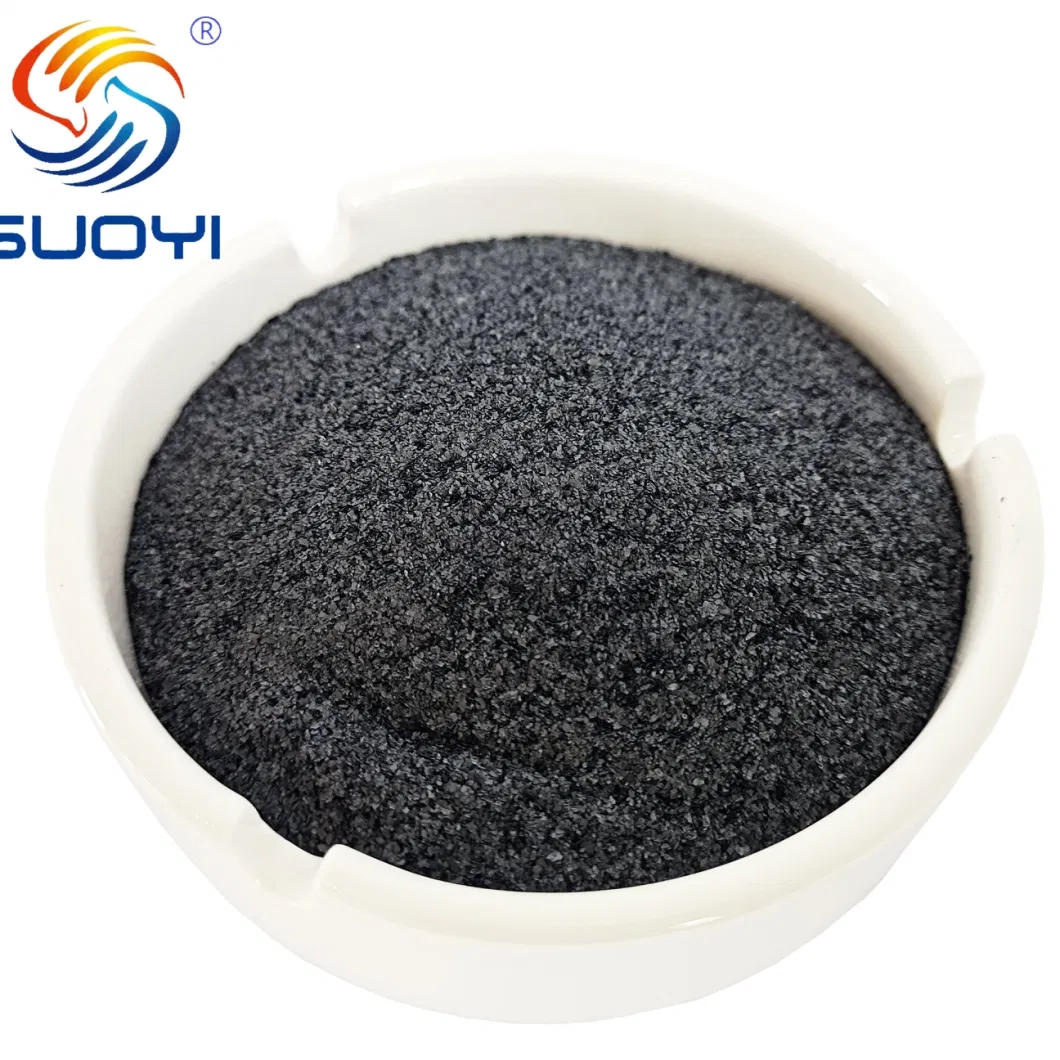

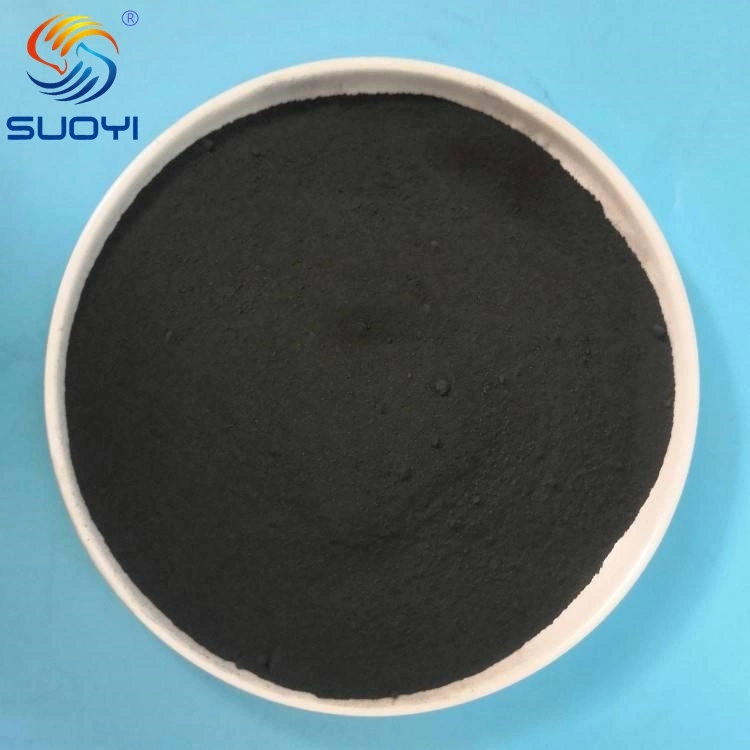

Colour |

Metal Grey Black |

|

CAS NO. |

12070-14-3 |

|

EINECS NO. |

235-125-1 |

|

Purity |

99.5% 99.9% |

|

Particle size |

0.5-1um 1-2um |

|

Melting point |

3540ºC |

|

Application |

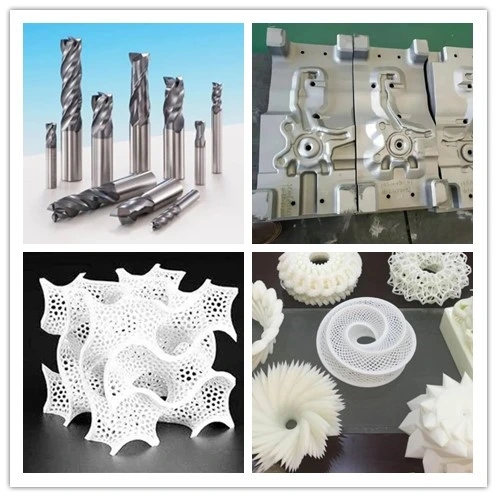

Igniter, Getter, Cermet Seal |

|

Package |

Drum/Barrel 10kgs/25kgs |

|

Origin |

Hebei,China |

Zirconium carbide, CAS number is 12070-14-3, the molecular formula is CZr, the molecular weight is 103.2347, it is a black solid, it needs to be sealed and protected from light at room temperature, in a ventilated and dry place. Zirconium carbide is a hard, high melting point material and has excellent high temperature resistance. Refractory materials. A raw material used as solid propellant in rocket engines. Used in the production of alloy steel. It is also the raw material for producing metallic zirconium and zirconium tetrachloride, as well as promising fine ceramic materials. Mainly used as abrasives, but also as raw materials for cemented carbide.

Zirconium carbide (ZrC) is an important high-temperature structural material with high melting point, high strength and corrosion resistance, and has the characteristics of efficiently absorbing visible light, reflecting infrared light and storing heat. New thermal insulation and temperature regulation textile and other fields.

1. Modifier of carbon-carbon composite functional materials - zirconium carbide (ZrC): zirconium carbide modified carbon fiber can greatly improve the strength of carbon fiber, increase fatigue resistance, wear resistance and high temperature resistance. At present, the modification of aerospace carbon fiber materials is widely used, and the effect is very obvious. The modified carbon fiber has been tested, and all indicators have surpassed the foreign level.

2. Zirconium carbide (ZrC) is used in the field of new thermal insulation and temperature regulation textiles: zirconium carbide has the characteristics of efficiently absorbing visible light and reflecting infrared rays. Energy can be stored in the material, which also has the property of reflecting infrared wavelengths beyond 2 μm. The wavelength of infrared rays generated by the human body is about 10 μm. When people wear zirconium carbide modified textile clothes, the infrared rays of the human body will not be easily emitted. This shows that zirconium carbide has ideal heat absorption and heat storage characteristics;

3. Zirconium carbide (ZrC) is used in cemented carbide, powder metallurgy and other fields, which can improve the strength and corrosion resistance of cemented carbide;

4. Zirconium carbide (ZrC) is used as a modifier for solid propellant grains in rockets and missiles.

1. High purity: the highest purity can reach 99.99%, there is no impurity phase detected by XRD, and the content of metal impurities detected by GDMS is low;

2. Small particle size: the minimum particle size is 30-50nm;

3. Centralized distribution: particle size standard normal distribution, no bimodal or multimodal, no tailing;

4. Typical products:

Standard 1-3um (D10>1.0um, D50: 1.2~1.8um, D90<3.0um, 80% particle size is concentrated in the range of 1-3um)

10-60um plasma thermal spraying cermet powder (D10>10.0um, D50: 20~30um, D90<60.0um,

80% particle size is concentrated in the range of 10-60um)

01

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director