- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

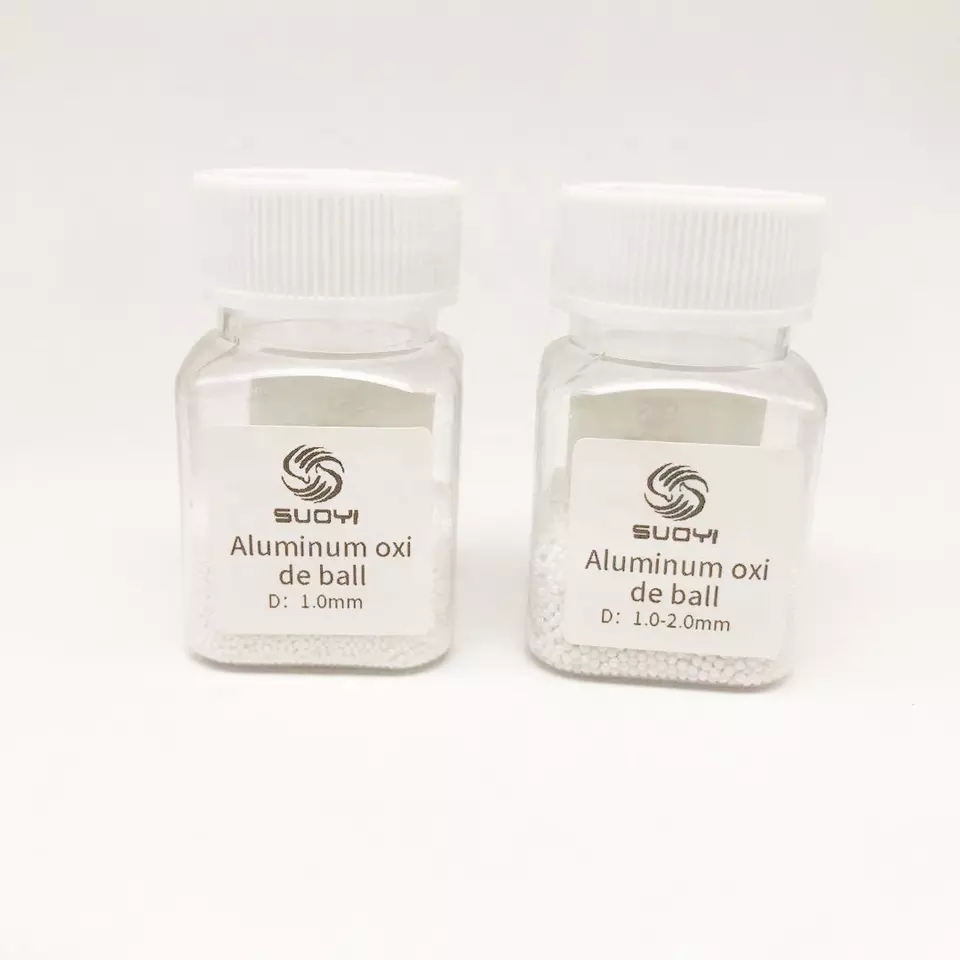

SUOYI 99%-99.99% Aluminum Oxide Ceramic Balls/92% Alumina Ball/Alumina Bead for Polishing

Alumina Grinding Beads Ceramic Ball Alumina Balls

Uses: Suitable for pumps, valves, flow meters, ceramic bearings, mechanical valves, chemical machinery, medical equipment, synthetic fiber manufacturing equipment, optical film equipment, various heat treatment furnaces, vacuum equipment and other harsh environments.

The toughness of alumina ceramics is relatively low. Compared with silicon nitride balls, alumina is more suitable for applications with lower cost requirements.

Features: 50% lighter than steel balls, wear-resistant; small friction coefficient, high temperature resistance, operating

temperature up to 1850 ° C; oil-free self-lubricating; more chemical corrosion resistance than steel; no metal pollution;

non-magnetic; electrical insulation

| item | value |

| Classification | ALUMINA |

| CAS No. | 1344-28-1 |

| Other Names | Alumina |

| MF | Al2O3 |

| EINECS No. | 215-691-6 |

| Place of Origin | China |

| Hebei | |

| Grade Standard | Industrial Grade |

| Purity | 92%-95% |

| Appearance | White ball |

| Application | wear and corrosion resistance industry, ceramic industry |

| Brand Name | Suoyi |

| Model Number | SY-706 |

| Molecular weight | 101.96 |

|

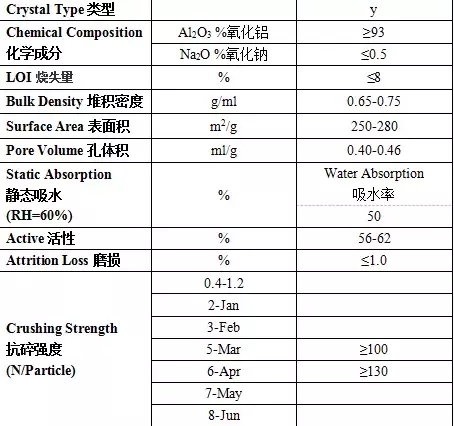

Properties |

Unit |

Standard Value |

|

Density |

g/cm3 |

≥6.08 |

|

Hardness |

KG/mm2 |

>1200 |

|

Modulus of Elasticity |

Gpa |

200 |

|

Thermal Conductivity |

W/(m.k) |

2(20-400℃) |

|

Thermal-expansion Coefficient |

10-6K-1 |

9.5 |

|

Crushing Load |

KN |

≥25(6.5mm) |

|

Flacture Toughness |

Mpa.m-1/2 |

8 |

|

Crystallite Size |

μm |

0.5 |

High alumina balls with more than 90% alumina content.

High alumina balls are widely used in different types of ceramics, enamels, glass, chemical industry due to their excellent characteristics such as high strength, high hardness, high wear resistance, large specific gravity, small size, high temperature resistance, corrosion resistance, and no pollution. Such as the finishing and deep processing of thick and hard materials in factories, among which high-alumina balls with a content of 92 are the most common.

Grinding and despersion for coatings,dyes and pigments;Grinding for magnetic materisals,piezoelectric ceramics,insulation materials and other fuctional materials.

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director