- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

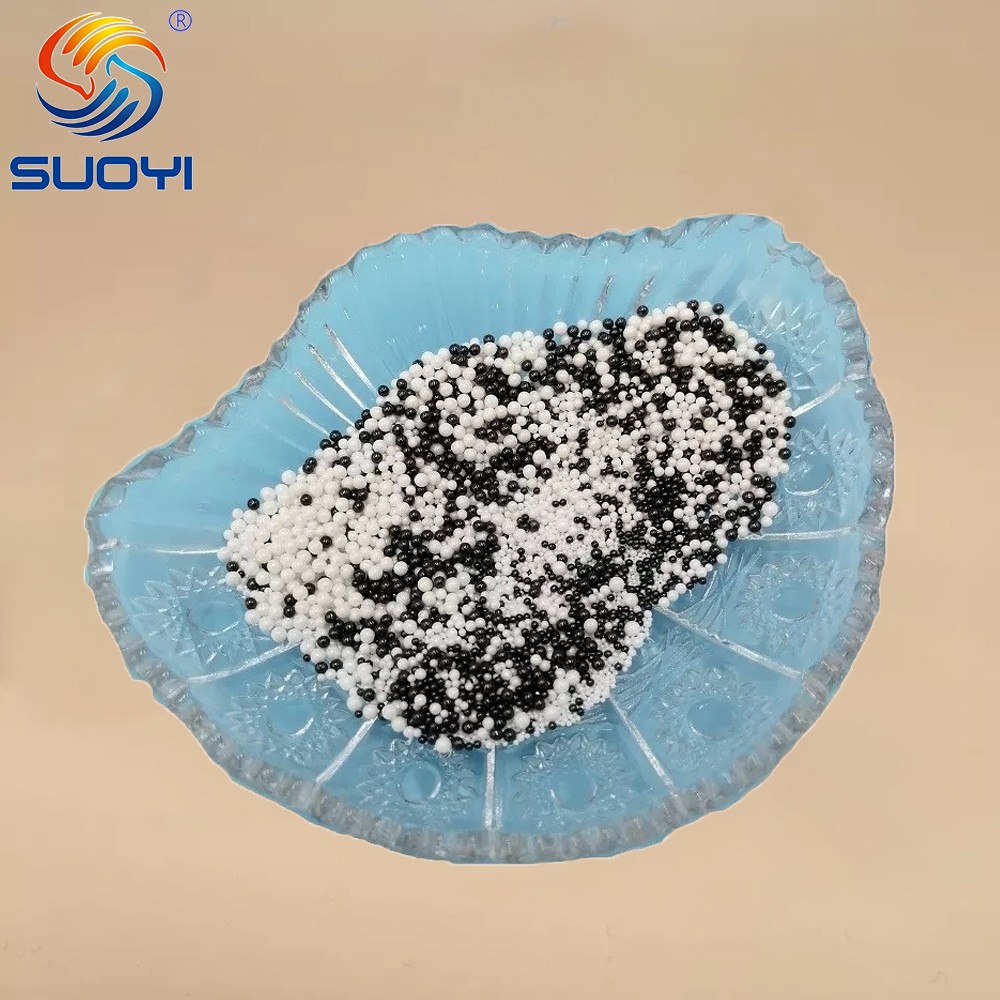

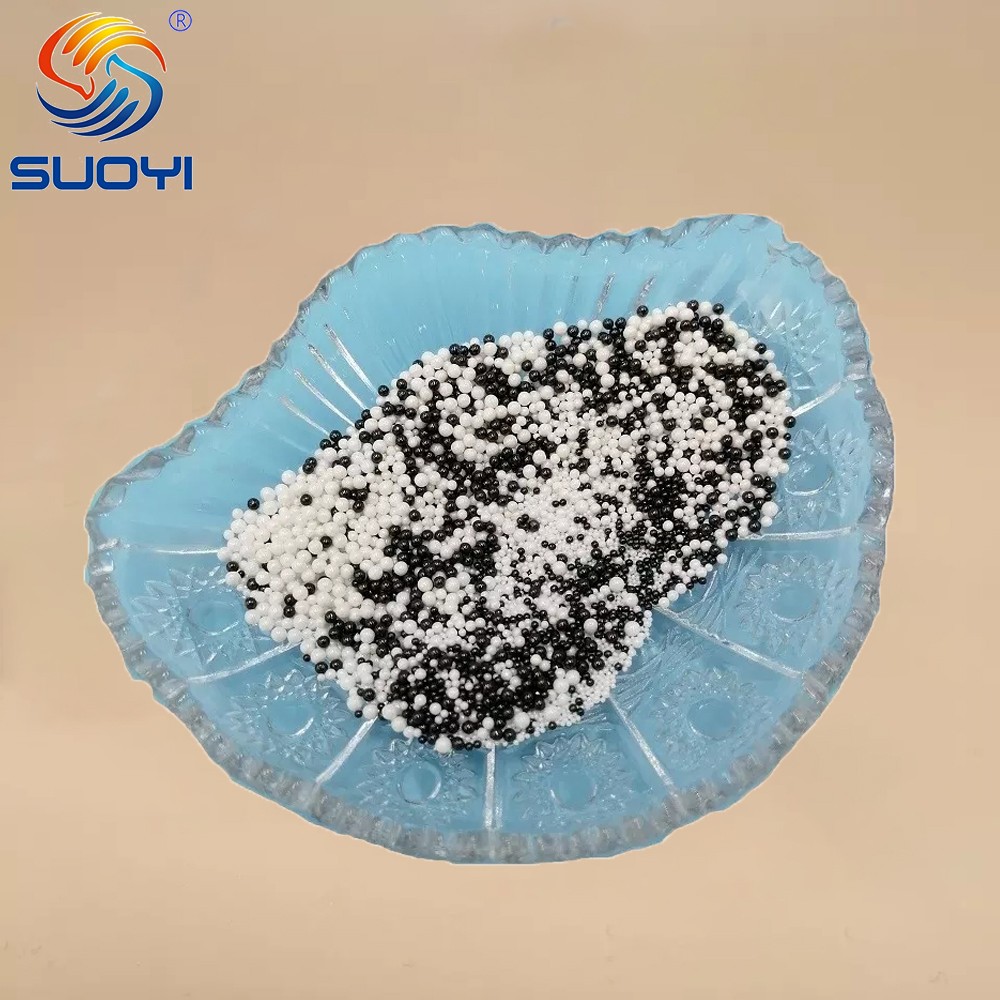

SUOYI 0.1mm-50mm Yttria Stabilized Zirconium Oxide Ceramic Beads/Balls Y2O3 Zro2 Balls

| Appearance | White black beads |

| Density | 5.87 g/cm3 |

| CAS Number | 1314-23-4 |

| EINECS Number | 215-227-2 |

| Melting point | 2054 ℃ |

| Boiling point | 2980 ℃ |

| Molecular Weight | 394.08 |

| Solubility | soluble inorganic acids, insoluble in water. |

| Packing | barreled, lined with plastic bag. Net weight per barrel 25kg |

1.Low doping requirements industries:magnetic material,piezoelectric ceramic and dielectric ceramics

2.Pollution prevention industries:medicine industry,food industry and cosmetic industry

3.Abrasion and corrosion resistant industries:coating,textiles industry,color industry,printing and dyeing industry

4.Different ceramic material industries:electronic ceramics,refractory ceramics and structural ceramics

The minimum size of zirconia beads is 0.05 mm, the commonly used ones are 0.4-0.6 mm, 0.6-0.8 mm, 0.8-1.0 mm, 1.8-2.0 mm, and the largest ones are 50 mm. Zirconia beads with particle size less than 3 mm are generally used in the sand mill, and some larger zirconia beads are also used in the ball mill tank.

| Product name | Yttrium Stabilized Zirconia Beads |

| Appearance | White |

| Purity | 94.8+/-0.2% ZrO2 5.2+/-0.2% Y2O3 |

| Usage | Electronic industry: piezoelectric ceramics, inductance materials, capacitor ceramics, semiconductor ceramics, etc.; Battery industry: lithium iron phosphate, lithium cobalt oxide materials, etc.; Chemical industry: paints, materials, inks, pigments, etc.; Ceramic industry: refractory materials, glazes, zirconium silicate, structural ceramics, etc.; Other industries: food, medicine, cosmetics, etc.; |

1.For grinding wear-resistant, corrosion-resistant products:oil paints, textile pigment, coating, ink and dyestufts.

2.For grinding high strength, high toughness products: magnetic materials, piezoelectric ceramics, dielectric ceramics.

3.To prevent pollution: medicine, food, cosmetics.

4.Ceramics: Electronic ceramics, refractory ceramics, structural ceramics.

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director