- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

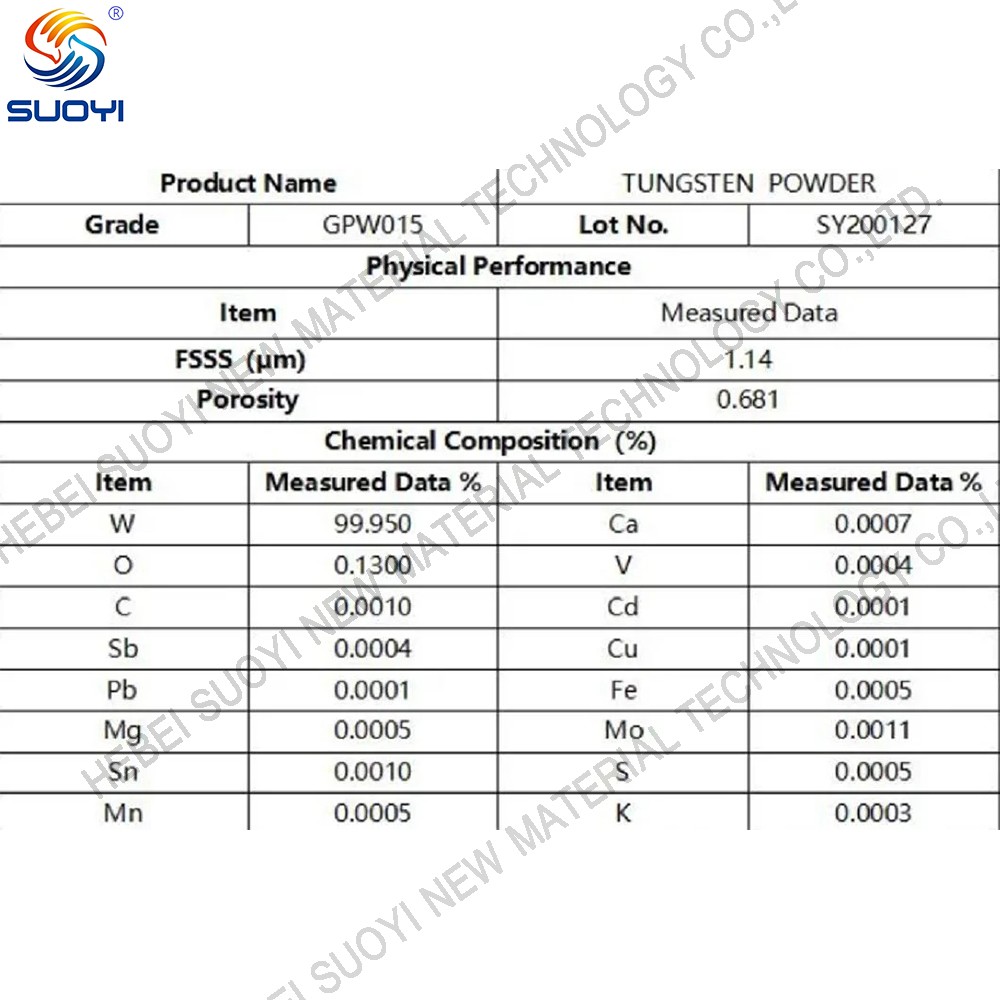

High-Purity Tungsten Powder Tungsten Carbide Powder Ultra-Fine Tungsten Powder

|

Application |

Thermal spraying, Coating material |

|

Shape |

spherical Powder, spherical Powder |

|

Material |

Cr20,Ni7.0C5.8,W, Cr20,Ni7.0C5.8,W |

|

Product name |

Chromium carbidi powder-WC-CrC-Ni |

|

Certification |

ISO9001 |

|

Color |

Gray |

|

Apperant density |

4.3-4.8g/cm3 |

|

advantage |

better antioxidant and anti-corrosion |

|

sample |

Availiable |

|

MOQ |

1kg |

|

Application |

Surface Spraying, Petroleum Industry |

|

Shape |

powder |

|

Material |

Tungsten Carbide |

|

Chemical Composition |

W/99.8;S/0.05max;P/0.07max |

|

Product name |

Sale Thermal Spray Fused WC Tungsten Carbide Powder For Spraying |

|

Application |

high melt point,good performance on anti-wear |

|

Color |

Silver Gray |

|

Dimensions |

0.38~0.85mm |

|

Purity |

95% |

|

Brand Name |

HR |

|

Keywords1 |

tungsten carbide wc powder |

|

Keywords2 |

tungsten carbide powder metallurgy |

|

Keywords3 |

wc powder |

|

Cast WC Tungsten Carbide powder composition – % |

||||

| Grade | WC-40100 | WC-40130 | WC-40140 | WC-40150 |

| W | 95-96 | 92-93 | 91-92 | 90-91 |

| T.C | 3.8-4.1 | 3.8-4.1 | 3.8-4.1 | 3.8-4.1 |

| F.C | ≦0.08 | ≦0.08 | ≦0.08 | ≦0.08 |

| Ti | ≦0.1 | ≦0.1 | ≦0.1 | ≦0.1 |

| Ni | / | 2.5-3.5 | 3.5-4.5 | 4.5-5.5 |

| Cr | ≦0.1 | ≦0.1 | ≦0.1 | ≦0.1 |

| V | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 |

| Si | ≦0.02 | ≦0.02 | ≦0.02 | ≦0.02 |

| Fe | ≦0.3 | ≦0.3 | ≦0.3 | ≦0.3 |

| O | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 |

| Product name | Chromium carbidi powder-WC-CrC-Ni |

| Tungsten carbide powder series | WC-NI10 WC-CrC-Ni WC-Co8 WC-Co12 WC-Co17 WC-Co10Cr4 |

| Material | Cr20,Ni7.0C5.8,W |

| Certification | ISO9001 |

| Place of origin | Deyang,China |

| price | 1-5kg :sample price over 5kg: bulk price |

| our service | Product customization, order tracking, double quality inspection, factory report |

| Size | -325mesh/+15um; -45um/+15um |

| advantage | better antioxidant and anti-corrosion |

| The usage | Plasma,HVOF |

| Sample | Availiable |

| Hardness(HV) | 1200 |

| Generation process | Agglomerate sintering |

| Name | Tungsten carbide Alloy powder |

| Other Name | Tungsten carbide powder,WC-Co10-Cr4 |

| CAS NO. | 12070-12-1 |

| Formula | WC-Co10-Cr4 |

| EINECS NO. | 235-123-0 |

| HS Code | 2849902000 |

| Grade | Industrial-grade |

| Use/Application | spraying,coating,casting,metallurgical |

| Package | Barrel,Iron Drum ,Plastic Bucket |

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director