- Product

- Industrial Zirconia

- Rare Earth Products

- Alumina

- Carbide

- Nitride

- Ceramic Products

- Graphite Products

- Nano Materials

- Spherical Spray Material

- High Purity Metal Powder

- Hot Selling Advanced Materials

01

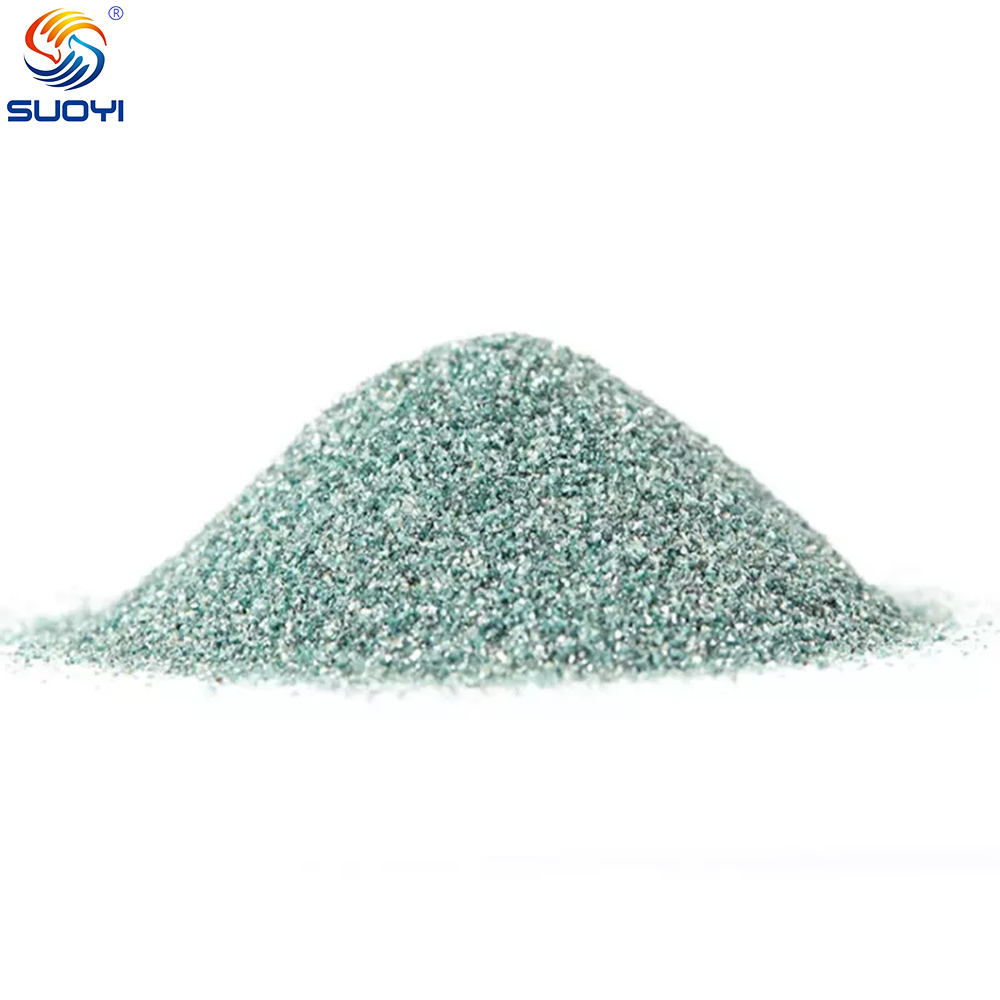

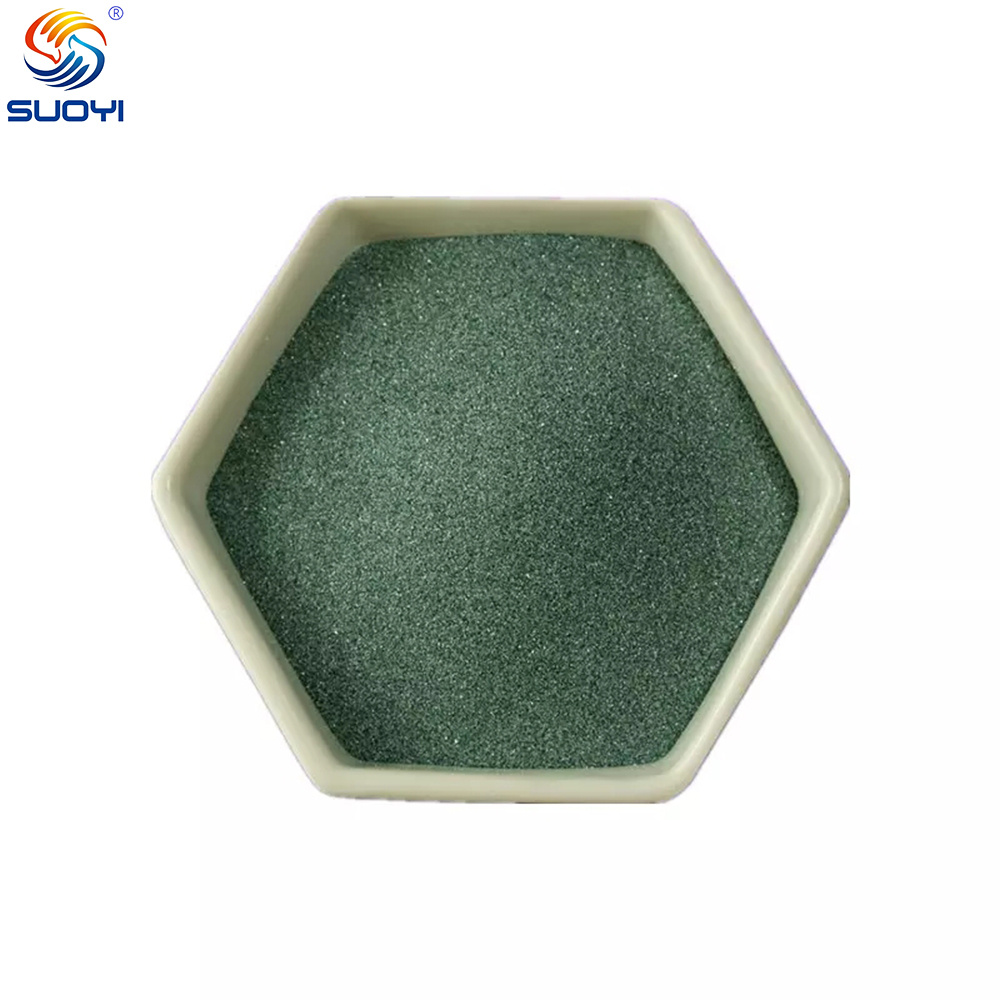

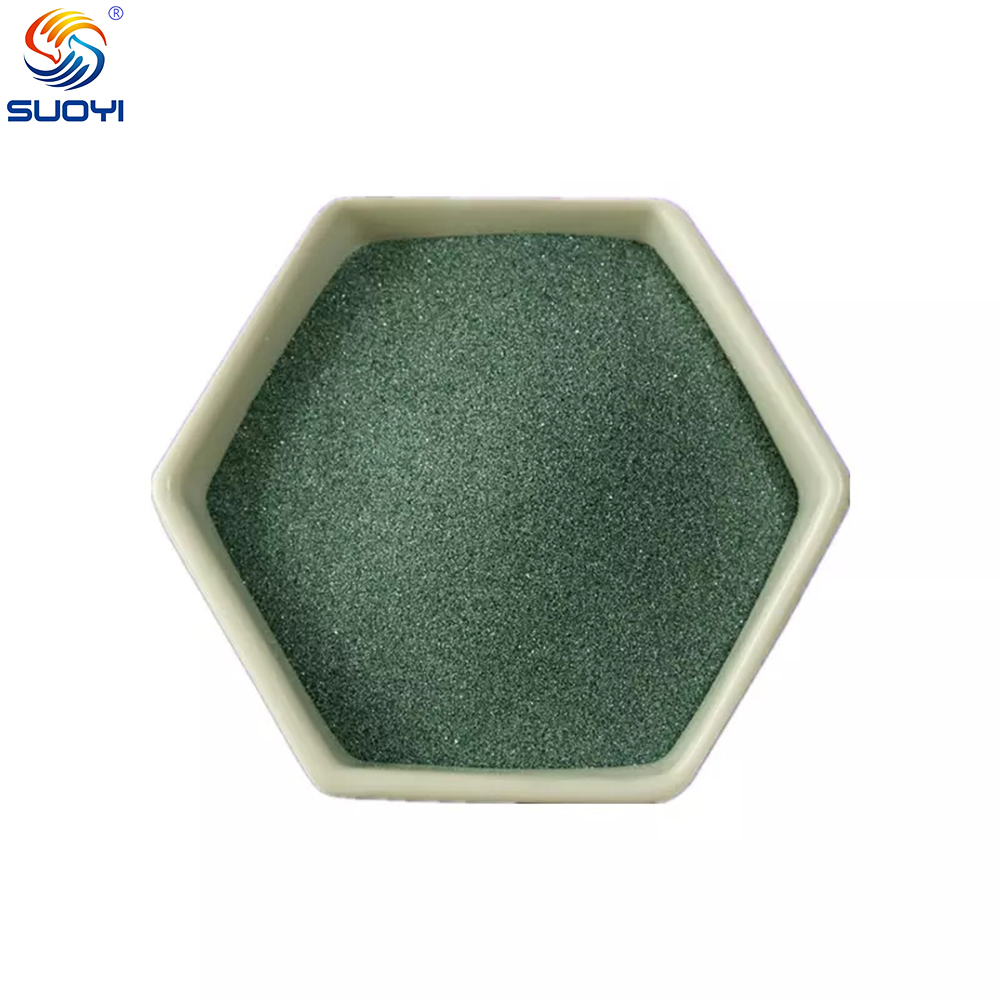

99.9% Spherical Silicon Carbide SiC Green powder for paint coating

| Product name | Silicon Carbide(Green) |

| Molecular formula | SiC |

| CAS | 409-21-2 |

| EINECS | 206-991-8 |

| Molecular weight | 40.0962 |

| Proportion | 3.2g/cm3 |

| Color | Green |

| Hardness | Mohs 9.5 |

| Silicon carbide has four main application areas, namely | Functional ceramics, advanced refractories, abrasives and metallurgical raw materials. |

|

tem |

value |

|

Place of Origin |

China |

|

Brand Name |

SUOYI |

|

Model Number |

SY-SC01 |

|

Alloy Specification |

|

|

Particle |

|

|

Name |

silicon carbide |

|

Usage |

ceramics |

|

Appearance |

green powder |

|

MOQ |

1kg |

|

Density |

3.2 g/cm³ |

|

Formula |

SiC |

|

Molecular Weight |

40.1 |

|

Solubility |

Insoluble |

|

Sample |

Available |

|

Brand |

SUOYI |

| Physical Properties | |

| Hardness | Knoop 2600 |

| Hardness | Mohs 9.4 min |

| Melting Point | 4712°F (2600°C) |

| Specific Gravity | 3.2g/cm3 |

| Particle Shape | Blocky, Sharp |

| Color | Green |

Green silicon carbide is made of petroleum coke and high-quality silica as the main raw materials, adding salt as an additive, and smelting at high temperature in a resistance furnace. It is green crystal, brittle and sharp, and has certain thermal conductivity and conductivity. The micro shape is hexagonal crystal. The Mohs hardness of green silicon carbide is 9.5, the micro hardness is 2940-3300kg/mm2, and the Knoop hardness is 2670-2815kg/mm2. It is higher than corundum in the abrasive, and only second to diamond, cubic boron nitride and boron carbide.

The density is generally considered as 3.20-3.25g/cm3. The natural bulk density of green silicon carbide abrasive is 1.2-1.6g/cm3, and the specific gravity is 3.20~3.25g/cm3. Green silicon carbide micro powder is made of high-quality large crystalline green silicon carbide blocks after crushing, vertical ball mill particle shaping, pickling water, hydraulic precision classification, natural sedimentation and drying at high temperature. It has stable quality, good crystallization, high surface cleanliness, no large particles, small content of fine particles, centralized particle size distribution, and high grinding efficiency. It is suitable for various precision grinding processes. The workpiece surface processed is uniform without scratches.

01

01

Mr. Perry Wu International Sales Director

Mr. Perry Wu International Sales Director